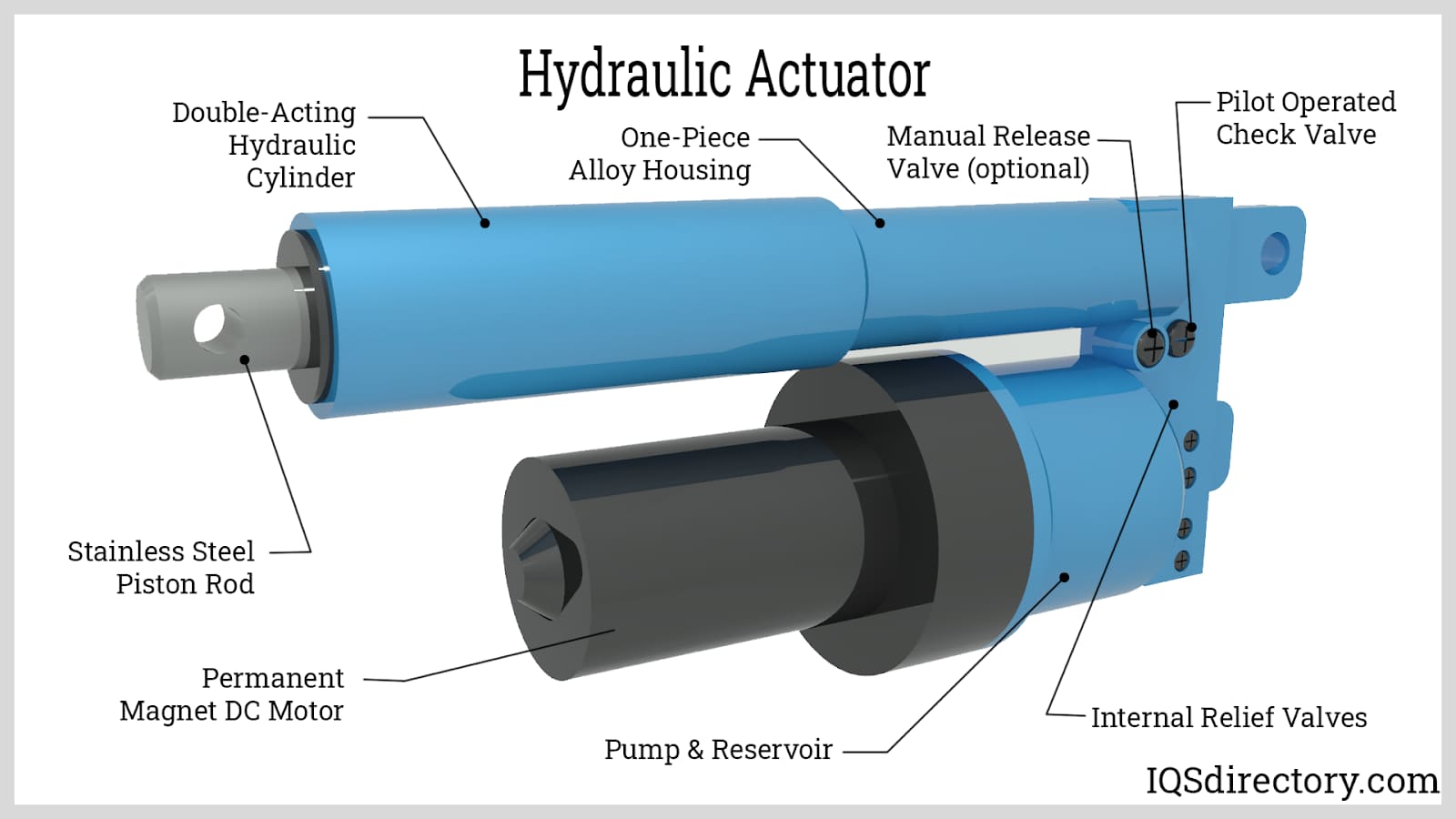

The definition of a hydraulic actuator is a device that converts the fluid’s pressure energy into mechanical motion. The hydraulic actuator consists of a cylinder or a fluid motor that uses hydraulic energy to operate mechanically. A rotational, linear, or oscillatory motion is produced as a result of the mechanical motion. Read More…

Aggressive Hydraulics is a leading manufacturer and designer of custom hydraulic cylinders. Since our founding in 2002 we have assembled a team of experienced professionals and talented engineers to assist us in creating the best hydraulic cylinders on the market. The component parts we offer include cylinder heads, end caps, mounts, pistons, ports, valve blocks, and other related accessories. To ...

We are a leading supplier of hydraulic cylinders. If you need a heavy duty hydraulic cylinder then Columbus Hydraulic Cylinders can make exactly what you are looking for. All of our standard products come with an o-ring and two back-up rings and these items can be featured with piston u-cups, slipper seals, special compounds, chevron, steel rings and more if your application requires. Give us a...

Phelps Industries specializes in hydraulic cylinders, heavy duty hydraulic cylinders, high pressure hydraulic cylinders, telescopic hydraulic cylinders and hydraulic cylinder repair. All our products have a comprehensive warranty program plus we provide top-quality technical service and support.

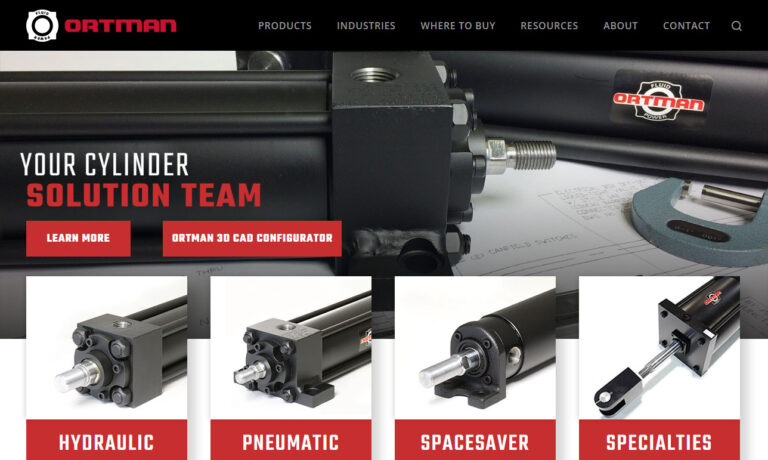

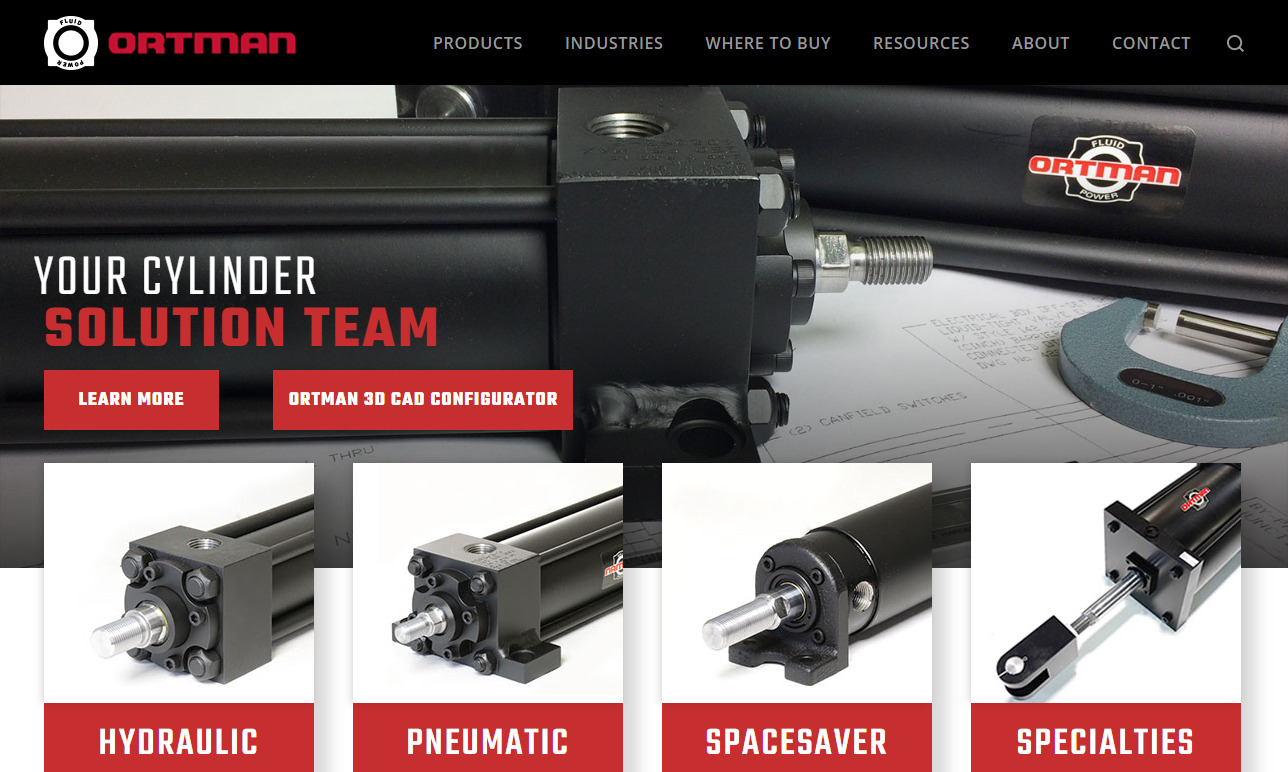

We are dedicated to serving customers in a global marketplace. Since our inception, we have been providing our customers with exceptional customer service and top of the line hydraulic cylinders that are built to last a lifetime. We have made it our goal to provide our customers with the technical assistance that they can count on to find solutions to all their problems, visit our website today...

More Hydraulic Actuator Manufacturers

A hydraulic actuator applies a lot of force while compressing liquids, which is almost seldom the case. According to the hydraulic actuator's operating concept, liquid pressure rather than instrument air pressure is used to exert pressure on the diaphragm, which subsequently moves the valve actuator and the position valve's stem. Almost all varieties of hydraulic actuators convert liquid pressure into mechanical power using a piston rather than a diaphragm.

Types of Hydraulic Actuators

Based on the method of actuation, hydraulic actuators can be divided into three categories: linear actuators, rotary actuators, and semi-rotary actuators.

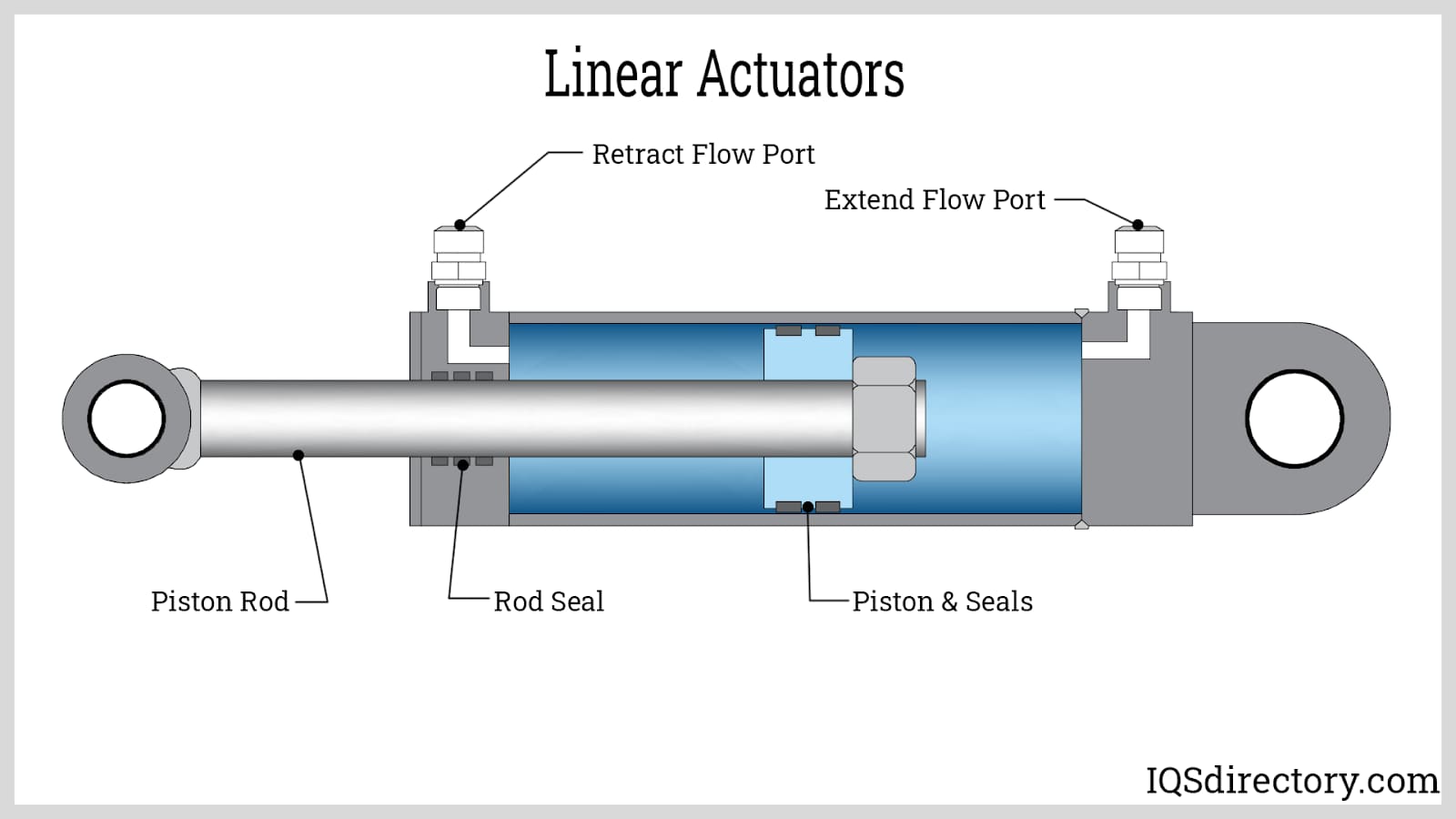

Linear Actuators: For linear actuation, a linear actuator is employed. These hydraulic actuators, also known as hydraulic cylinders, provide the force or motion in a straight line.

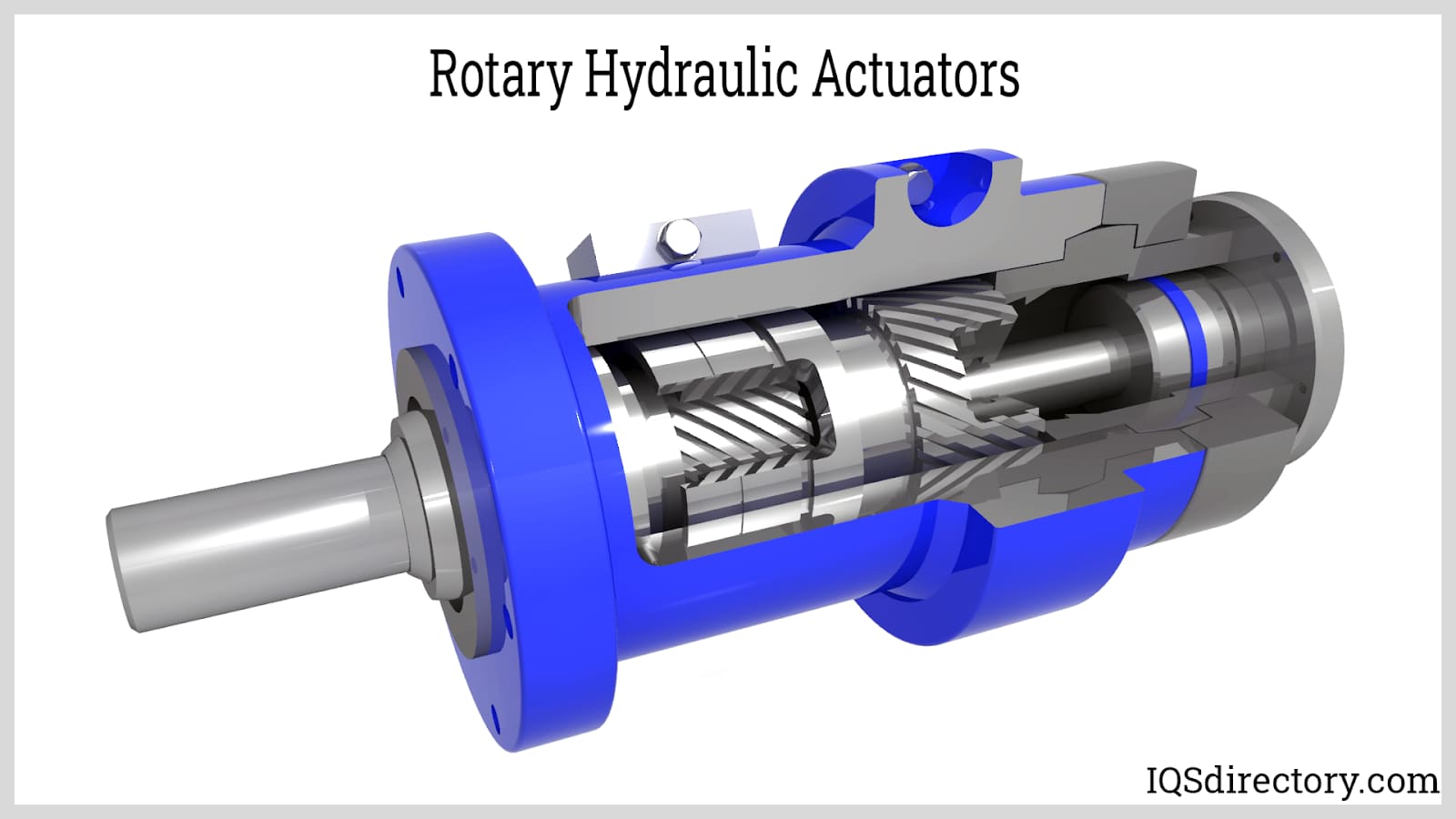

Rotary actuator: These hydraulic actuators are known as hydraulic motors because they produce torque or rotational motion. These actuators can achieve constant angular movement.

The partial angle of actuation is accomplished using the semi-rotary actuator. Although 360 degrees or less is more common, semi-rotary actuators are capable of partial angular movements that can be many complete revolutions.

Working Principle of Hydraulic Actuators

This system primarily relies on Pascal's Law, which asserts that when pressure is applied to a finite fluid inside a container at a specific place, the pressure will transfer uniformly and without loss through all of the liquid's channels and the container's walls.

The output force due to an applied force will be as follows if pressure (P) is applied to an area (A):

F = P * A

When a specified force, such as "F," is used to create pressure, such as "P," in a restricted fluid, the force that is generated on a larger area may be somewhat greater than the force created by the pressure. This technology produces incredibly strong forces by applying pressure to a specific point. Therefore, many hydraulic systems make use of this principle.

A main cylinder, also known as a power cylinder, and a spool valve, sometimes known as a pilot valve, are the essential parts of a hydraulic actuator. This hydraulic actuator can be operated in the same way. The piston moves translationally when there is a difference in pressure between the two regions of the main cylinder. By dividing the main cylinder through the main piston, two regions and two chambers were acquired for the main cylinder. The spool valve in the cylinder allows the rate of fluid delivery within the cylinder to be adjusted.

This valve has four ports, each of which can be linked to a different system component. While the other two ports are connected independently to the two chambers inside the main cylinder, the first two distinct ports are connected to the drain area and fluid supply, respectively. The spool valve is initially located at the neutral position; therefore, there is no fluid flow inside the main cylinder. The fluid flows in the hydraulic actuator, which causes the load to shift as a result. Therefore, the output displacement will be zero when the input displacement is "0." The fluid passes from the high-pressure source to the left side chamber in the main cylinder when the input displacement forces the spool valve to turn in the right direction. As a result, the left chamber of the cylinder experiences more force than the right chamber, which allows for the generation of an accelerating force that moves the load. In this instance, the load advances in the direction of the fluid's flow. The force needed to move the valve is much smaller than the force needed to move the load, acting as power amplification. As a result, hydraulic actuators will function in this manner.

Advantages of a Hydraulic Actuator

- Simple design

- Inexpensive

- Dependable construction

- High levels of force

- Protection against overloads for the engine

- Functions at 4,000 psi

- Maintains stable pressure and torque

Disadvantages Of a Hydraulic Actuator

- Inflexibility

- High level of upkeep

- Able to feel temperature

- Akills to partially control motion

- Require a number of complementing components to reduce noise, including a liquid reservoir, pump, motor, heat exchangers, and release valves

- Loss of fluids can result in decreased effectiveness and hygienic issues, which may cause harm to nearby objects and structures

Applications of Hydraulic Actuators

- Applications dependent on high forces

- Automatic jacks

- Extremely accurate placement for large weights

- Controlling the speed of the oh close-loop

- Hydrostatic ram

- Applications requiring a sensing function

Choosing the Proper Hydraulic Actuator Manufacturer

To ensure you have the most constructive outcome when purchasing hydraulic actuators from a hydraulic actuator manufacturer, it is important to compare several companies using our directory of hydraulic actuator manufacturers. Each hydraulic actuator manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each hydraulic actuator business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple hydraulic actuator companies with the same form.

Hydraulic Cylinders

Hydraulic Cylinders Hydraulic Lifts

Hydraulic Lifts Hydraulic Motors

Hydraulic Motors Hydraulic Presses

Hydraulic Presses Hydraulic Pumps

Hydraulic Pumps Hydraulic Seals

Hydraulic Seals Hydraulic Valves

Hydraulic Valves Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services