Like all hydraulic cylinders, these devices convert the hydraulic energy of fluids under pressure into mechanical energy. This generates the linear force and motion needed to move machine linkages and any attached loads. Read More…

Aggressive Hydraulics is a leading manufacturer and designer of custom hydraulic cylinders. Since our founding in 2002 we have assembled a team of experienced professionals and talented engineers to assist us in creating the best hydraulic cylinders on the market. The component parts we offer include cylinder heads, end caps, mounts, pistons, ports, valve blocks, and other related accessories. To ...

We are a leading supplier of hydraulic cylinders. If you need a heavy duty hydraulic cylinder then Columbus Hydraulic Cylinders can make exactly what you are looking for. All of our standard products come with an o-ring and two back-up rings and these items can be featured with piston u-cups, slipper seals, special compounds, chevron, steel rings and more if your application requires. Give us a...

Phelps Industries specializes in hydraulic cylinders, heavy duty hydraulic cylinders, high pressure hydraulic cylinders, telescopic hydraulic cylinders and hydraulic cylinder repair. All our products have a comprehensive warranty program plus we provide top-quality technical service and support.

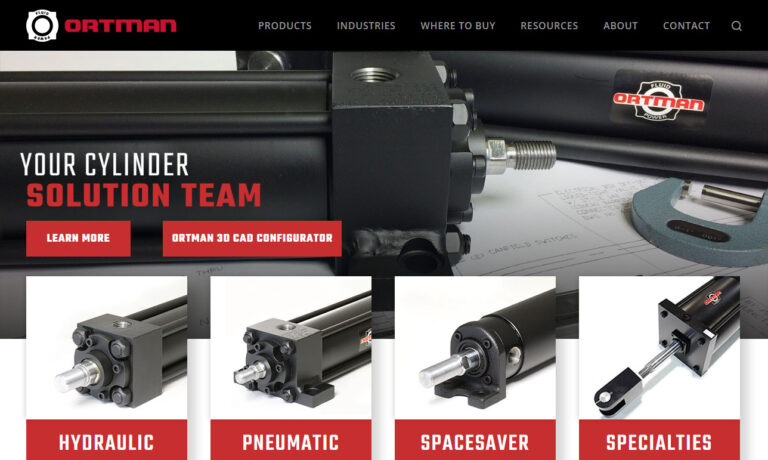

We are dedicated to serving customers in a global marketplace. Since our inception, we have been providing our customers with exceptional customer service and top of the line hydraulic cylinders that are built to last a lifetime. We have made it our goal to provide our customers with the technical assistance that they can count on to find solutions to all their problems, visit our website today...

More Stainless Steel Hydraulic Cylinder Manufacturers

While a number of durable materials can be used in the construction of hydraulic cylinders, stainless steel is particularly well suited to the wear, friction and corrosion common to industrial hydraulics applications. Composed of at least 10% chromium, this group of steel alloys develops a thin layer of chromium oxide. This film-like layer is what makes the steel stainless. It also contributes to its heightened resistance to corrosion and, in some instances, self-repairing abilities.

These attributes are vital to food, medical, water treatment, fishing, environmental technology, petrochemical and many more industries where cylinder components may encounter volatile fluids or be cleaned hygienically. While the choice of material is important, there are several other considerations to take into account when selecting the proper cylinder for a given application. Additional concerns include body type, stroke, operating pressure, maximum working pressure, rod diameter and bore diameter.

Despite the many variables in hydraulic cylinder construction, the basic design is relatively simple and uniform. A round, rectangular tube shaped barrel, most often extruded stainless steel tubing, makes up the main body of the cylinder. This barrel houses and connects all of the components. At either end is a cap which closes off the tube, making the body into an enclosed chamber.

In one or both caps, however, is a seal through which the piston rod may move in and out. This cold-rolled piece of steel is only partially exposed, while the rest of it is hidden within the cylinder where it is attached to a piston. The hydraulic piston is a disc shaped piece of stainless steel that fits exactly in the cross section of the barrel, thus dividing the chamber into two smaller compartments. Precision machined like the endcaps, the piston face is surrounded by seals which prevent fluid from leaking between the compartments or out of the cylinder altogether.

Each section within the barrel also has a port through which high pressure hydraulic fluid is introduced and released. When the fluid is forced into the section of the cylinder below the piston, the rod is extended while the inverse retracts it. The protruding end of the rod is attached to the load or machine linkages to be moved. Although the cylinder itself can offer only linear motion, clevis fittings can provide angular movement when needed.

Hydraulic Cylinders

Hydraulic Cylinders Hydraulic Lifts

Hydraulic Lifts Hydraulic Motors

Hydraulic Motors Hydraulic Presses

Hydraulic Presses Hydraulic Pumps

Hydraulic Pumps Hydraulic Seals

Hydraulic Seals Hydraulic Valves

Hydraulic Valves Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services