A simple device, hydraulic cylinders are usually made up of two main parts: an outer cylinder barrel containing hydraulic fluid, and a hydraulic piston which is connected to a rod which moves it up and down inside the barrel. Read More…

Aggressive Hydraulics is a leading manufacturer and designer of custom hydraulic cylinders. Since our founding in 2002 we have assembled a team of experienced professionals and talented engineers to assist us in creating the best hydraulic cylinders on the market. The component parts we offer include cylinder heads, end caps, mounts, pistons, ports, valve blocks, and other related accessories. To ...

We are a leading supplier of hydraulic cylinders. If you need a heavy duty hydraulic cylinder then Columbus Hydraulic Cylinders can make exactly what you are looking for. All of our standard products come with an o-ring and two back-up rings and these items can be featured with piston u-cups, slipper seals, special compounds, chevron, steel rings and more if your application requires. Give us a...

Phelps Industries specializes in hydraulic cylinders, heavy duty hydraulic cylinders, high pressure hydraulic cylinders, telescopic hydraulic cylinders and hydraulic cylinder repair. All our products have a comprehensive warranty program plus we provide top-quality technical service and support.

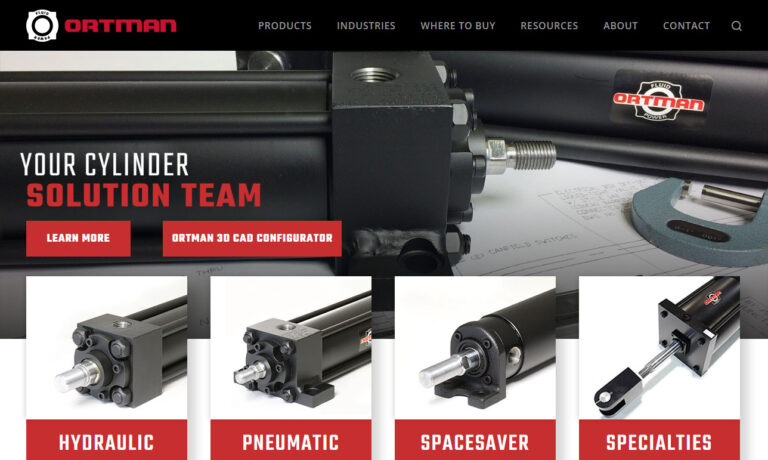

We are dedicated to serving customers in a global marketplace. Since our inception, we have been providing our customers with exceptional customer service and top of the line hydraulic cylinders that are built to last a lifetime. We have made it our goal to provide our customers with the technical assistance that they can count on to find solutions to all their problems, visit our website today...

More Hydrolic Cylinder Manufacturers

The distance that a piston travels with the cylinder until it is fully extended is known as its stroke. The length of a stroke is often used to classify the cylinder and this length can range widely from less than an inch to several feet in length in relation to the power required.

Hydraulic cylinders are used commonly in automobiles in the transmission, brakes, steering, in aviation, industrial and construction machinery for example as excavators. Hydraulic cylinders are typically one of two types: tie-rod cylinders or welded cylinders. Both systems are similar in that the outer cylinder barrel is typically made of steel or aluminum, and the maximum pressure that the cylinder can sustain is directly related to the maximum output of the hydraulic cylinder.

They can be single-action or double-acting designs depending on whether a cylinder's piston produces pressurized motion in one direction or in both directions. The piston is located inside the barrel housing and is commonly chrome-plated to prevent any deterioration due to wear and tear or corrosion.

Most often, the hydraulic fluid used in a cylinder is an oil. This will need to be periodically replaced or refilled as it is affected slowly by the process of pumping the piston. Other hydraulic systems use water as the motion fluid which is less expensive than hydraulic oil, and does not result in pollution, making water hydraulic cylinders an environmentally friendlier solution. There are a number of factors to consider regarding hydrolic cylinders such as the maximum power, the mounting and configuration setup of the machine itself in relation to elements to be worked on, the materials used in the cylinders and the stroke itself.

As the motion produced by the pressure inside hydraulic cylinders is linear, the machine components should not be placed under any indirect tension or strength as it may cause damage to the parts which would result in loss of pressure, and therefore loss of power. To ensure the best results from the machine, the cylinders should only be used for pushing and pulling. Hydraulic cylinders range in price according to their capabilities but are an investment at any size. However, due to the potential power output of even a small hydraulic system, the paybacks are often satisfactory.

Hydraulic Cylinders

Hydraulic Cylinders Hydraulic Lifts

Hydraulic Lifts Hydraulic Motors

Hydraulic Motors Hydraulic Presses

Hydraulic Presses Hydraulic Pumps

Hydraulic Pumps Hydraulic Seals

Hydraulic Seals Hydraulic Valves

Hydraulic Valves Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services