A hydraulic ram is a pump that operates by cycling and draws energy from water (hydropower). Hydraulic rams move a porton of a large volume of water at a lower level to a higher level without using external energy. For a hydraulic ram pump to function, it’s crucial to have enough water at a low height for the ram pump to be able to move it. Read More…

Aggressive Hydraulics is a leading manufacturer and designer of custom hydraulic cylinders. Since our founding in 2002 we have assembled a team of experienced professionals and talented engineers to assist us in creating the best hydraulic cylinders on the market. The component parts we offer include cylinder heads, end caps, mounts, pistons, ports, valve blocks, and other related accessories. To ...

We are a leading supplier of hydraulic cylinders. If you need a heavy duty hydraulic cylinder then Columbus Hydraulic Cylinders can make exactly what you are looking for. All of our standard products come with an o-ring and two back-up rings and these items can be featured with piston u-cups, slipper seals, special compounds, chevron, steel rings and more if your application requires. Give us a...

Phelps Industries specializes in hydraulic cylinders, heavy duty hydraulic cylinders, high pressure hydraulic cylinders, telescopic hydraulic cylinders and hydraulic cylinder repair. All our products have a comprehensive warranty program plus we provide top-quality technical service and support.

We are dedicated to serving customers in a global marketplace. Since our inception, we have been providing our customers with exceptional customer service and top of the line hydraulic cylinders that are built to last a lifetime. We have made it our goal to provide our customers with the technical assistance that they can count on to find solutions to all their problems, visit our website today...

More Hydraulic Ram Manufacturers

The hydraulic ram pump operates on a concept called "Water Hammer." When a moving fluid or gas is abruptly halted, the result is a surge of pressure from the change in momentum. Water hammer is a relatively frequent occurrence whenever there is flowing fluid.

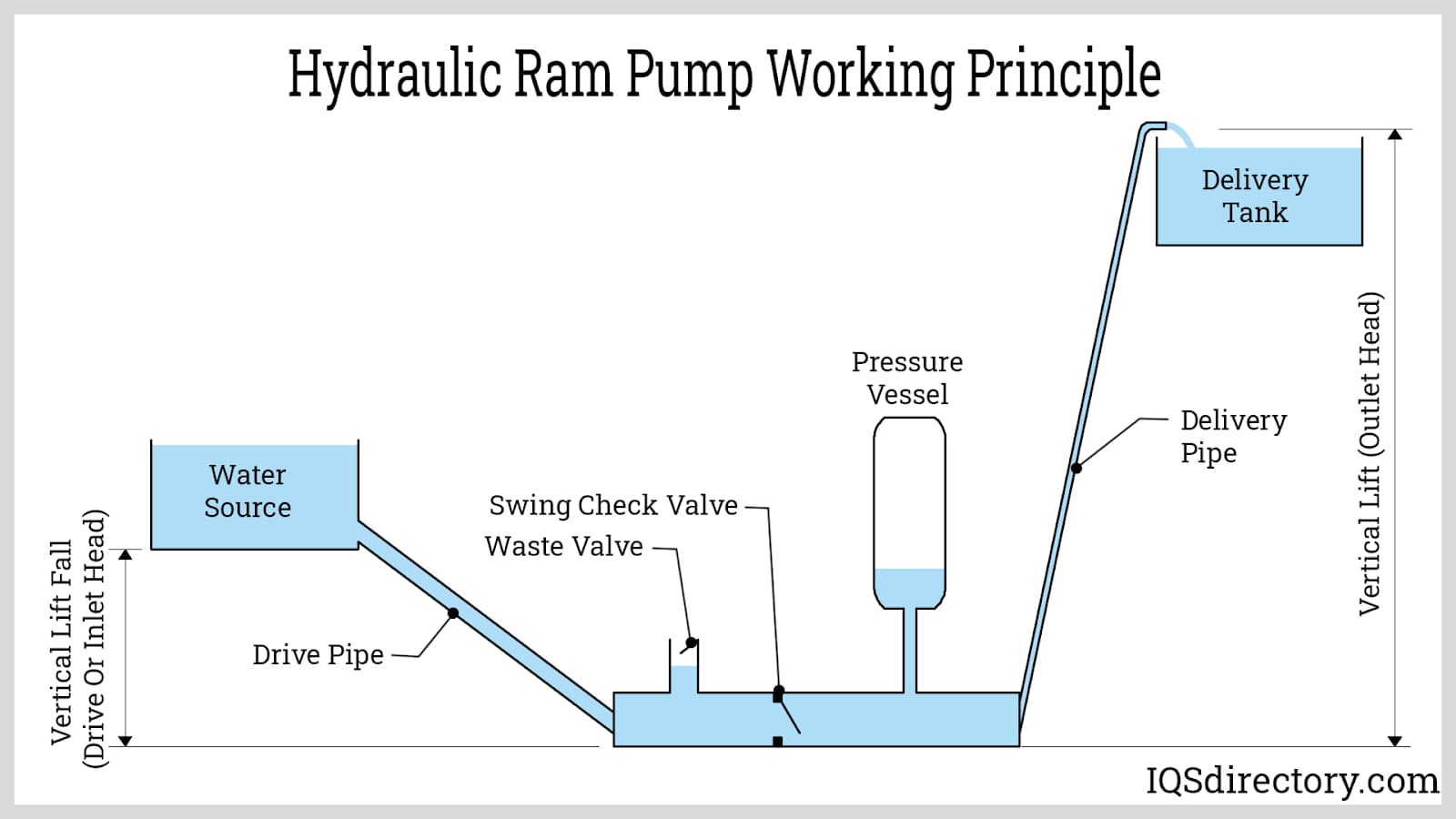

Working Principle of Hydraulic Ram

A hydraulic ram works on the same principal as a water hammer, which is that when flowing water is abruptly stopped, the change in water's momentum increases pressure. The increased pressure forces some water to rise to a higher level. The water valve is initially open, whereas the delivery work valve is initially closed. Under the influence of the earth's gravity, the water from the supply tank starts to flow and gains up speed, creating kinetic energy. This continues until the exhaust valve finally has to close. The momentum of the water flow in the pipe that is providing it against now closes the waste or exhaust valve, which in turn results in a water hammer and increases the pressure of water in the chamber. Momentum is defined as mass times speed. Due to the water's high pressure, the delivery valve opens, allowing water to enter the vessel with air within. This further compresses the vessel's already-existing tension. As a result, the air vessel experiences excessive pressure, which causes the delivery valve to close. Currently, the delivery pipe is being forced to pass water from the air vessel. The waste or exhaust valve and the delivery pipe are both still closed in this scenario. As the pressure inside the valve chamber gradually decreases, the exhaust or waste valve once more opens, allowing the water to pass through. Then, the water supply pipes begin to circulate water once more, causing the valve chamber to experience water hammer. This loop repeats itself.

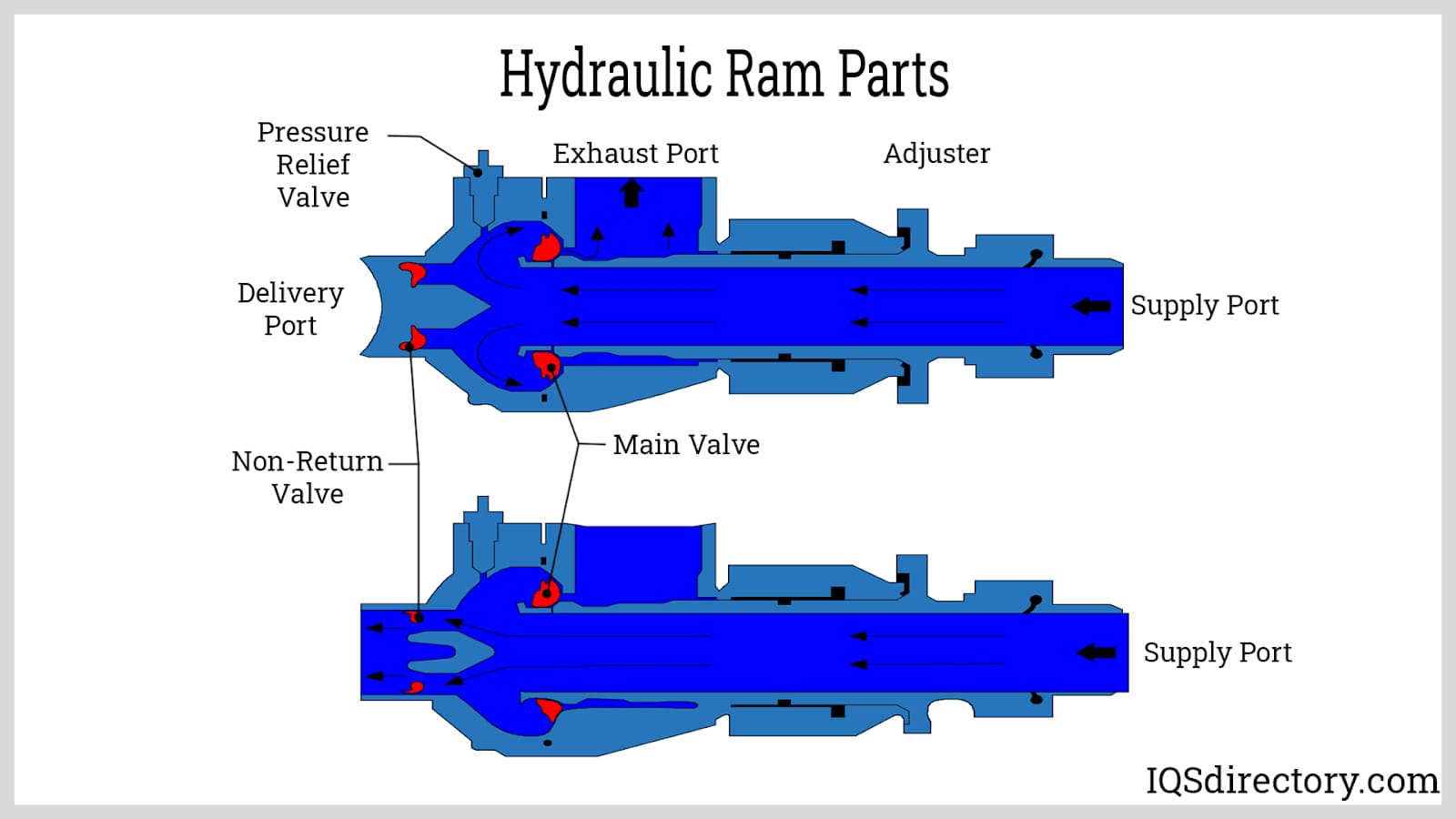

Important Parts of The Hydraulic Ram

Parts of the hydraulic ram pump are:

- Supply tank

- Supply pump

- Valve chamber

- Waste valve

- Delivery valve

- Air vessel

- Delivery pipe

- Delivery tank

Advantages Of the Hydraulic Ram

- Since a hydraulic ram doesn’t require manual operation.

- Repair, maintenance, and operation are inexpensive.

- Its operating costs are likewise quite low.

- Electricity isn’t required to operate a hydraulic ram.

- Since it operates continually, a predictable output will result.

Disadvantages Of the Hydraulic Ram

- A hydraulic ram pump is extremely noisy when it operates.

- Hydraulic Rams are limited in their applications.

- The installation cost may be expensive.

Applications Of The Hydraulic Ram

- Hydraulic ram pumps lifts drinking water from springs to the surface

- It may be installed wherever there is a water flow.

- Hydraulic pumps work well in hilly places where low level water needs to be raised uphill for use.

- Hydraulic ram pumps work well in locations with restricted access to alternative power sources.

Uses of Hydraulic Ram

A hydraulic ram is a sizable apparatus in which the pressure of a fluid displaces a piston or plunger. A piston and a sealed cylinder make up a hydraulic ram. The piston is forced upward as oil enters one side of the cylinder. The car's front end was raised using a hydraulic ram.

Conclusion

The hydraulic ram pump is a significant possibility that makes use of the plentiful surface water in our nation. Although the initial expenditures of installing a hydraulic ram are significant, maintaining one only costs a very small amount of money to operate.

Choosing the Proper Hydraulic Ram Manufacturer

To ensure the most productive outcome when purchasing a hydraulic ram from a hydraulic ram manufacturer, it is important to compare several companies using our directory of hydraulic ram manufacturers. Each hydraulic ram manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each hydraulic ram manufacturer website using our patented website previewer to quickly learn what each hydraulic ram business specializes in. Then, use our simple RFQ form to contact multiple hydraulic ram companies with the same form.

Hydraulic Cylinders

Hydraulic Cylinders Hydraulic Lifts

Hydraulic Lifts Hydraulic Motors

Hydraulic Motors Hydraulic Presses

Hydraulic Presses Hydraulic Pumps

Hydraulic Pumps Hydraulic Seals

Hydraulic Seals Hydraulic Valves

Hydraulic Valves Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services