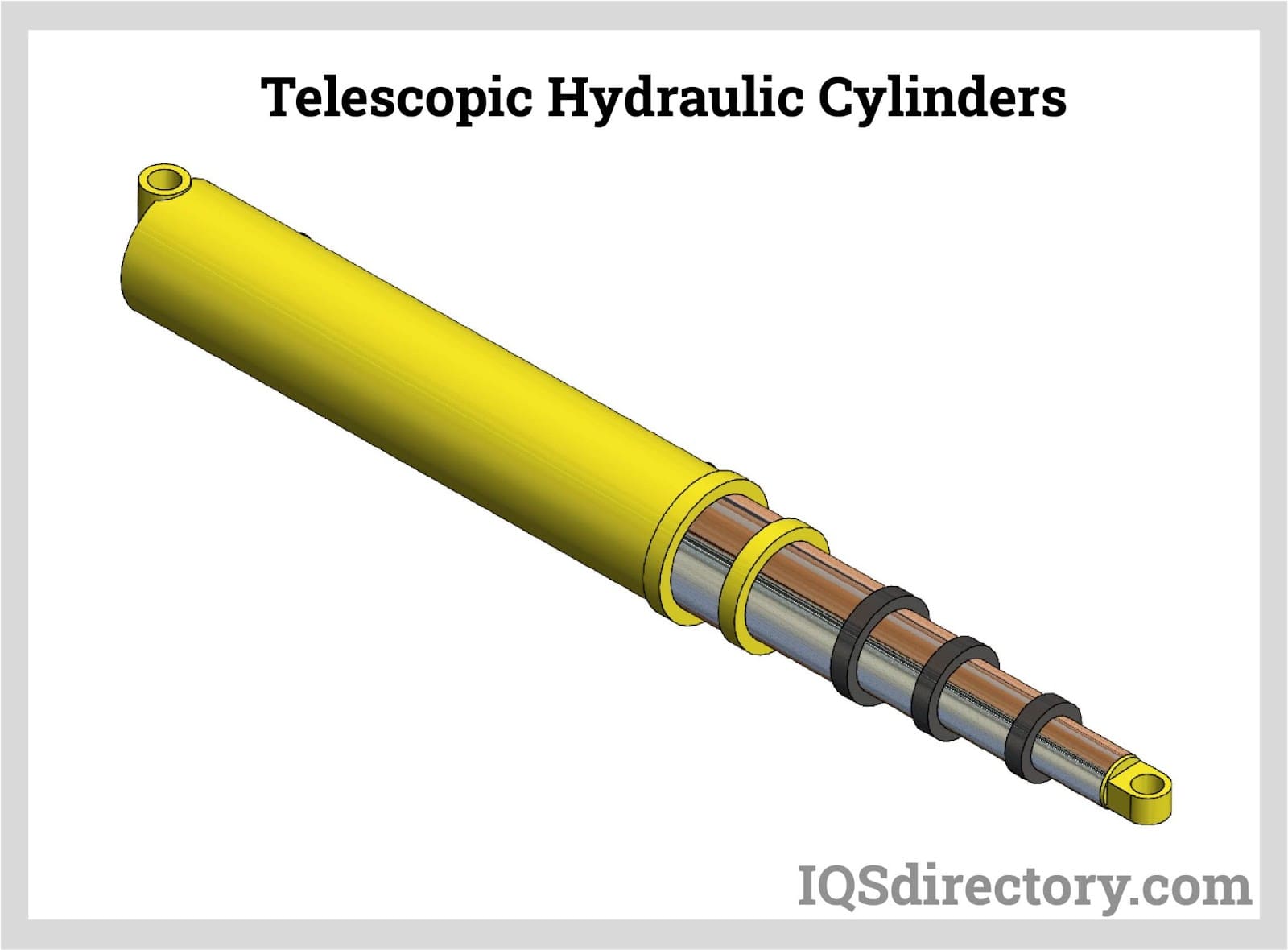

Telescopic hydraulic cylinders, also known as multi-stage cylinders, are linear actuators made of stacked sleeves on tubular rods. Four to five sleeves of shrinking diameters are stacked inside of one another. Hydraulic pressure can expand the largest sleeve (the main or barrel). Once the barrel has completed its full stroke, the following sleeve (called a stage) starts extending. This procedure repeats until the plunger, the cylinder’s final stage. The moment the cylinder’s pressure is released, the force of the load forces the oil out of the system, and the cylinder retracts. Read More…

Aggressive Hydraulics is a leading manufacturer and designer of custom hydraulic cylinders. Since our founding in 2002 we have assembled a team of experienced professionals and talented engineers to assist us in creating the best hydraulic cylinders on the market. The component parts we offer include cylinder heads, end caps, mounts, pistons, ports, valve blocks, and other related accessories. To ...

We are a leading supplier of hydraulic cylinders. If you need a heavy duty hydraulic cylinder then Columbus Hydraulic Cylinders can make exactly what you are looking for. All of our standard products come with an o-ring and two back-up rings and these items can be featured with piston u-cups, slipper seals, special compounds, chevron, steel rings and more if your application requires. Give us a...

Phelps Industries specializes in hydraulic cylinders, heavy duty hydraulic cylinders, high pressure hydraulic cylinders, telescopic hydraulic cylinders and hydraulic cylinder repair. All our products have a comprehensive warranty program plus we provide top-quality technical service and support.

We are dedicated to serving customers in a global marketplace. Since our inception, we have been providing our customers with exceptional customer service and top of the line hydraulic cylinders that are built to last a lifetime. We have made it our goal to provide our customers with the technical assistance that they can count on to find solutions to all their problems, visit our website today...

More Telescopic Hydraulic Cylinder Manufacturers

Types of Telescopic Hydraulic Cylinders

Telescopic hydraulic cylinders are available in two varieties: single-acting and double-acting.

Single-Acting Telescopic Cylinders

In single-acting cylinders, retraction is initiated by gravity or external force. Single-acting telescopic cylinders are designed to extend with hydraulic pressure and retract with an outside force. They provide dependable, long-lasting performance and often have a wider outer diameter than rod cylinders. Single-acting telescopic cylinders are prevalent on dump trucks, platform trucks, and trailers.

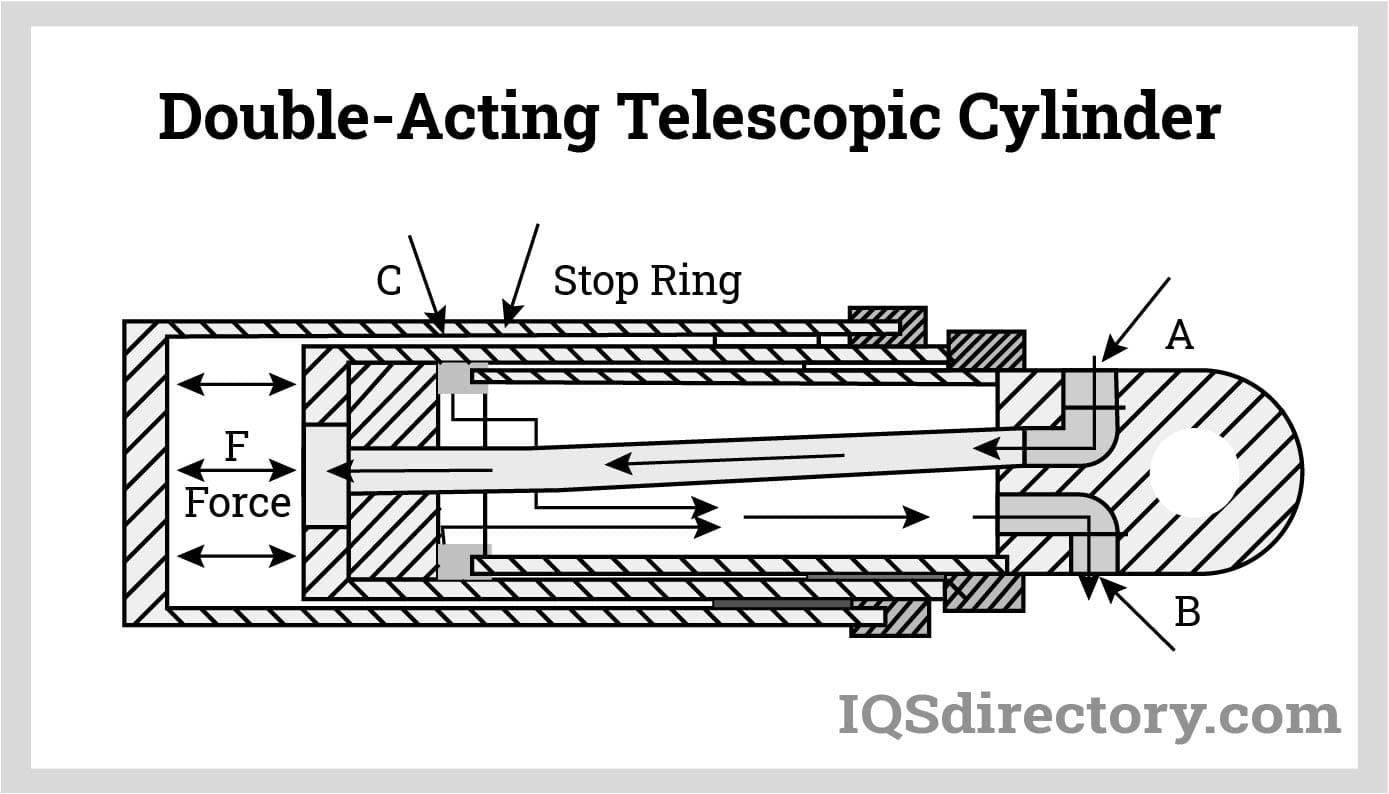

Double-Acting Telescopic Cylinders

Double-acting telescopic cylinders need hydraulic pressure to both extend and retract. They work well when horizontally mounted cylinders or other obstacles prevent gravity from assisting. Double-acting cylinders are frequently employed in transfer trailers, waste trucks, and non-critical positioning applications.

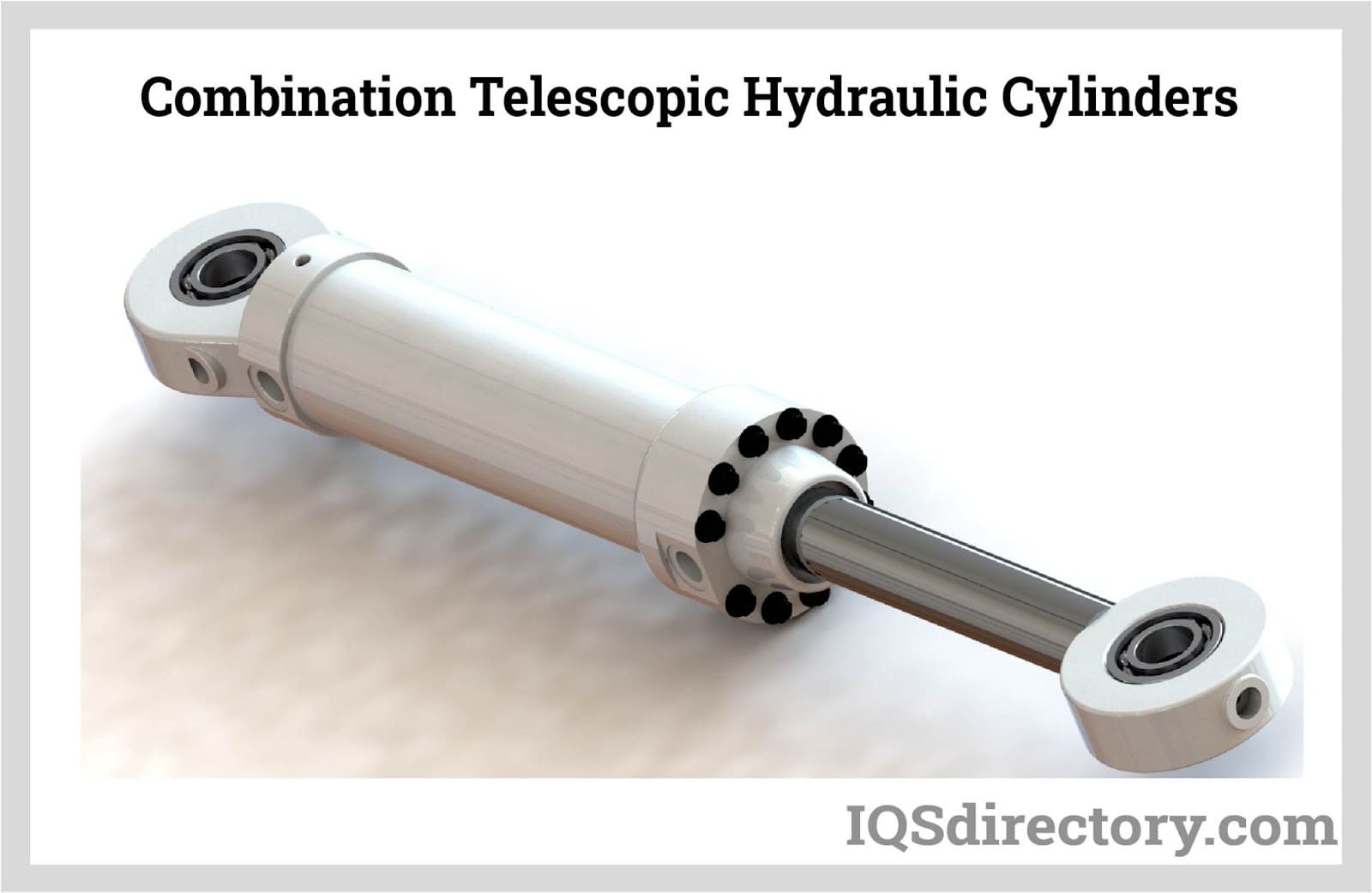

Combination Telescopic Hydraulic Cylinders

Combination telescopic cylinders can be single-acting or double-acting. This means they’ll use hydraulic pressure for a portion of the stroke, then retract via gravity or external force. These multi-stage telescopic cylinders are used for heavy-duty applications like huge mobile drilling rigs. Hydraulic power is used more often than pneumatic telescopic cylinders when moving heavy weights. Telescopic hydraulic cylinders are used when extension starts from a small location because their collapsed length is 20 - 40% of the fully extended length. Combination telescopic cylinders use a longer working stroke than single-stage rod-style actuators. Dump trucks, elevators, and garbage trucks use telescopic cylinders.

Application Of Telescopic Cylinders

Pneumatic telescopic cylinders still exist, despite the prevalence of hydraulic power. Hydraulic power is more dependable for moving large weights. For example, a dump truck must tilt its load to a 60-degree angle to empty its contents. Hydraulic telescopic cylinders are a sensible option for this application.

Benefits Of Telescopic Hydraulic Cylinders

The telescopic hydraulic cylinder's small size, long stroke capacity, and ability to achieve specific angles are its main advantages. The hydraulic system is user-friendly and compact because it can retract.

Choosing the Right Telescopic Hydraulic Cylinder Supplier

To ensure you have the most beneficial outcome when purchasing telescopic hydraulic cylinders from a telescopic hydraulic cylinder supplier, it is important to compare several companies using our directory of telescopic hydraulic cylinder suppliers. Each telescopic hydraulic cylinder supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each telescopic hydraulic cylinder business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple telescopic hydraulic cylinder businesses with the same form.

Hydraulic Cylinders

Hydraulic Cylinders Hydraulic Lifts

Hydraulic Lifts Hydraulic Motors

Hydraulic Motors Hydraulic Presses

Hydraulic Presses Hydraulic Pumps

Hydraulic Pumps Hydraulic Seals

Hydraulic Seals Hydraulic Valves

Hydraulic Valves Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services